Tips & Tricks

HID Card Reader Upgrades with Bluetooth to Modernize Legacy PACS

February 2, 2024 • bluetooth hid reader, hid iclass, Proximity Cards

Enhancing Legacy Access Control Systems: Tech Tips for Upgrading HID Card Readers with Bluetooth In the ever-evolving landscape of access control systems, ensuring the security...

Tips & Tricks

Network Tips For HID FARGO HDP Card Printers For Enterprise ID

September 22, 2023 •

Enterprise Security ID Using HID FARGO HDP Printer Ethernet Connection Using an Ethernet connection on a Fargo HDP card printer for enterprise ID card systems...

Tips & Tricks

How to Build a High Volume Enterprise ID Badge System

April 21, 2022 • HID Global, High-Volume Printing, ID Card Printer, ID Card Security Features

Enterprise Level ID Systems Does your organization have multiple sites, departments, role functions, and thousands of employees to identify? Are you growing, acquiring or merging...

Articles

How Visitor Management Systems Verify Legitimate ID Cards

March 15, 2022 • ID Issuance, Visitor Management Solutions

Visitor Management Software Confirms Legitimate Guests What types of technologies does your organization use to prepare your workforce for incoming customers and visitors? What verification...

Articles

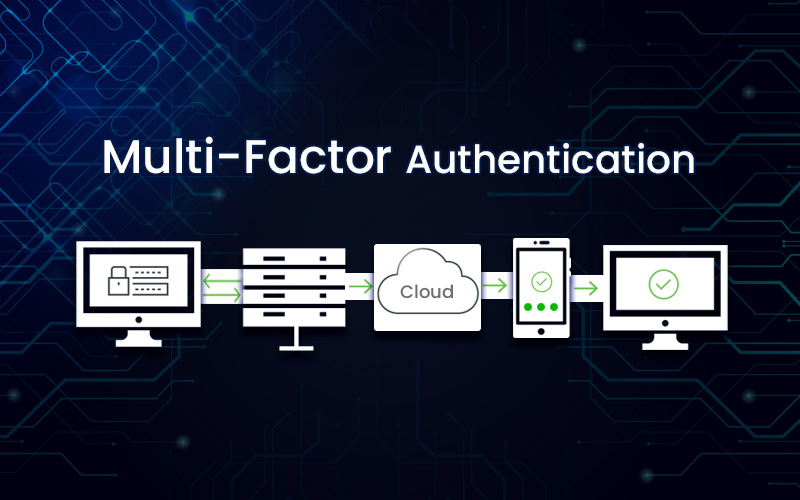

MFA: An Essential Part of Cybersecurity for Remote Employees

February 11, 2022 • Hybrid Workforce, Multi-Factor Authentication, System Upgrades

Cybersecurity Risks for Remote Workers: The recent, massive shift to remote working has presented newer challenges to IT departments and how they manage logical access....

Articles

Tips On Integrated Security for Critical Infrastructure Facilities

February 9, 2022 • ID Issuance, Physical Access Control System, System Upgrades, Visitor Management Solutions

Visitor Management Systems; A Crucial Piece in Integrated Security for Critical Infrastructure Facilities What ways are you combating threats to ensure the safety of your...

Tips & Tricks

Same-Day Order Processing with AdvantIDge

May 2, 2017 • Support Plans, System Upgrades

ADVANTIDGE is ready to fulfill all of your security needs the same day, right away. As a longtime member of the security industry, ADVANTIDGE understands...

Tips & Tricks

Two Shortcuts To Avoid When Printing ID Cards

February 9, 2017 • ID Card Printer, ID Card Security Features

Most people are looking for ways to save a few bucks, save time, or both. When it comes to ID card printing, you might be...

Industries Served

Workplace Safety – OSHA Visitor Management Guidelines

November 29, 2016 • ID Issuance, Security Compliance, Visitor Management Solutions

Workplace Safety OSHA publishes many reports which often include recommended guidelines designed to increase workplace safety. While these recommendations aren’t official OSHA “regulations,” they are...

Tips & Tricks

RGB Versus CMYK – The Color Creation Process

November 22, 2016 • Consumables, ID Card Printer

Color Producing Technologies There are two different color technologies at work when it comes to the colors we produce. RGB - Red/Green/Blue, affects what we...